Out with the Clogs, In with the Flow:

Drain Hose & Condensate Pump Replacements

Upgrade your system with our drain hose and condensate pump replacements! We swap out dirty, black and worn vinyl tubing, we upgrade vinyl for PVC, replace pumps and tubing, and add condensate neutralizers with monthly bead replacements to keep everything flowing smoothly. No more leaks, just peak performance!

Reach out to us today, and let us assist you in finding the ideal fit for your home with care and expertise. See our FAQ at the bottom of the page for any general questions you may have!

VINYL HOSES, PVC, CONDENSATE PUMPS & NEUTRALIZERS

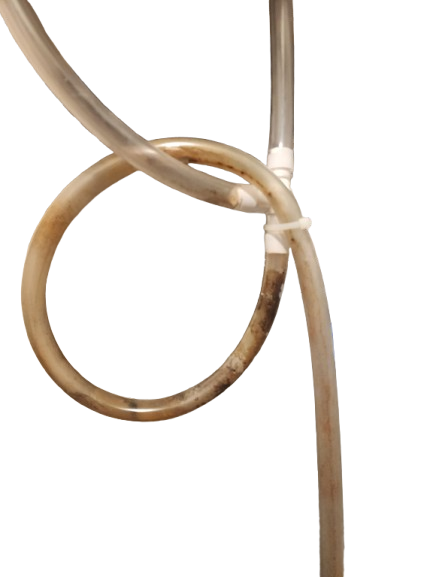

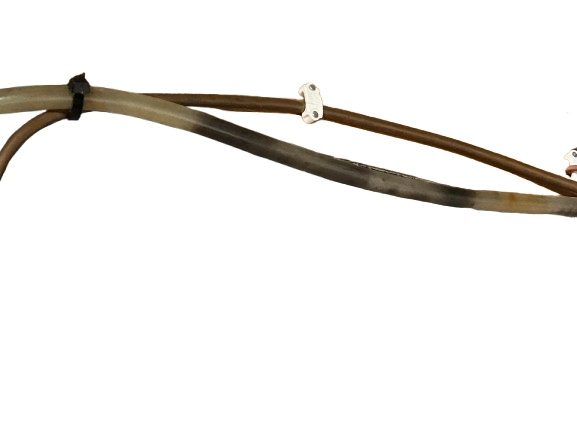

Drain tubing or PUMP look like this?

Prevent leaks & Water Damage.

FAQs: Dirty Drain Tubing, Broken Condensate Pumps, and PVC Upgrades

-

Over time, drain tubing can accumulate debris, algae, and dirt, leading to blockages that can cause leaks or poor drainage. Dirty or clogged tubing can also become brittle and prone to cracking, leading to system failures. Replacing your dirty drain tubing ensures proper drainage, reduces water damage risk, and keeps your HVAC system running efficiently.

-

A damaged condensate pump can cause water to back up into your system, leading to leaks, water damage, and potential system failure. If your pump isn’t working properly, it’s important to have it replaced quickly to avoid these issues. We offer fast and reliable condensate pump replacements to keep your system draining properly.

-

PVC tubing is a more durable, long-lasting solution compared to traditional materials like vinyl. It has a larger opening, which allows for better drainage and reduces the chances of clogging. PVC tubing also resists cracking, bending, and wear over time, providing a stronger and more efficient drainage system.

-

Signs that your condensate pump or tubing may need replacing include frequent water backups, visible cracks or leaks, and unusual noises coming from the pump. If your system isn't draining properly or if you notice pooling water, it’s time to have it inspected and potentially replaced.

-

While cleaning the tubing can help clear minor blockages, if the tubing is cracked, brittle, or heavily clogged, replacement is often the more effective solution. Old tubing can also harbor mold or algae, which can contribute to ongoing issues.

-

Yes! Replacing old or damaged components will improve drainage, reduce the risk of leaks, and help your HVAC system run more efficiently. Upgrading to PVC tubing, in particular, provides better water flow and can even extend the life of your system.

-

If your vinyl tubing is cracked, clogged, or showing signs of wear, it’s time for an upgrade. PVC tubing is a more durable alternative, especially for systems that experience regular water flow. If you notice pooling water, frequent blockages, or leaks, upgrading to PVC can address these issues.

-

While PVC tubing may have a slightly higher initial cost than vinyl, it offers better long-term value. PVC requires less maintenance, has a longer lifespan, and reduces the risk of costly repairs due to leaks or system failures.

-

Upgrading to PVC tubing typically takes just a few hours, depending on the complexity of your system. Our technicians will ensure a quick, professional installation with minimal disruption to your daily routine.

-

If left unreplaced, damaged black vinyl tubing can cause water to back up, resulting in leaks, mold growth, and potential damage to your HVAC system. Over time, a clogged or damaged tube can lead to more expensive repairs.

-

We recommend upgrading to durable PVC tubing. But any clear vinyl tubing is also a better choice than black vinyl. PVC offers better water flow, greater resistance to wear and tear, and a longer lifespan, making it a reliable alternative to black vinyl tubing.

-

The final cost can vary based on several factors, including the size of your system, the amount of tubing that needs to be replaced, any additional repairs or maintenance required, and the region you’re located in. For an accurate quote, it’s best to schedule a consultation.

-

Yes, we offer free estimates and consultations to assess the condition of your drain tubing and provide a detailed quote based on your specific needs.

-

Condensate pumps typically last about 5 to 10 years. However, if you notice any signs of malfunction, it’s best to replace the pump sooner rather than later to avoid system failure. Regular maintenance checks can help extend the life of your pump.

-

Our condensate pump replacement service includes removing the old pump, inspecting surrounding components, installing the new pump, and ensuring that the drainage system works properly. We’ll also provide you with advice on maintaining the pump and preventing future issues.

-

The cost of replacing or upgrading a condensate pump typically ranges. For a more accurate estimate based on your system, contact us today for a free consultation.

-

A condensate neutralizer is a device installed in your HVAC system to treat acidic water produced by the system’s condensation. It neutralizes the acidic properties of the condensate before it enters the drain, helping to prevent damage to pipes, drains, and other components due to corrosion.

-

Without a condensate neutralizer, the acidic condensate from your HVAC system can cause long-term damage to your drain pipes and other plumbing. This corrosion can result in leaks, clogs, and costly repairs. A neutralizer helps protect your system by balancing the pH levels of the condensate, preventing damage to your pipes and HVAC system.

-

A condensate neutralizer typically contains a bed of material, such as limestone or other neutralizing agents, which interacts with the acidic water to raise the pH level. As the condensate passes through the neutralizer, it becomes less acidic, reducing the risk of corrosion in your pipes and system.

-

Condensate neutralizers require periodic maintenance to ensure they continue functioning properly. The neutralizing media (e.g., limestone beads) needs to be replaced regularly—typically every 6 to 12 months—depending on usage. Our team offers monthly bead replacement services to keep your neutralizer working efficiently.

-

If the beads in your condensate neutralizer are not replaced, they can lose their ability to neutralize the acidic condensate. This could result in corrosion of your pipes and system, potentially leading to expensive repairs and decreased system efficiency.

-

The cost of installing a condensate neutralizer typically ranges between $150 and $400, depending on your HVAC system and the type of neutralizer used. Monthly bead replacement services are usually an additional cost of about $50 to $150 depending on the service plan. Contact us for an accurate estimate tailored to your system.